Technical Parameters Table

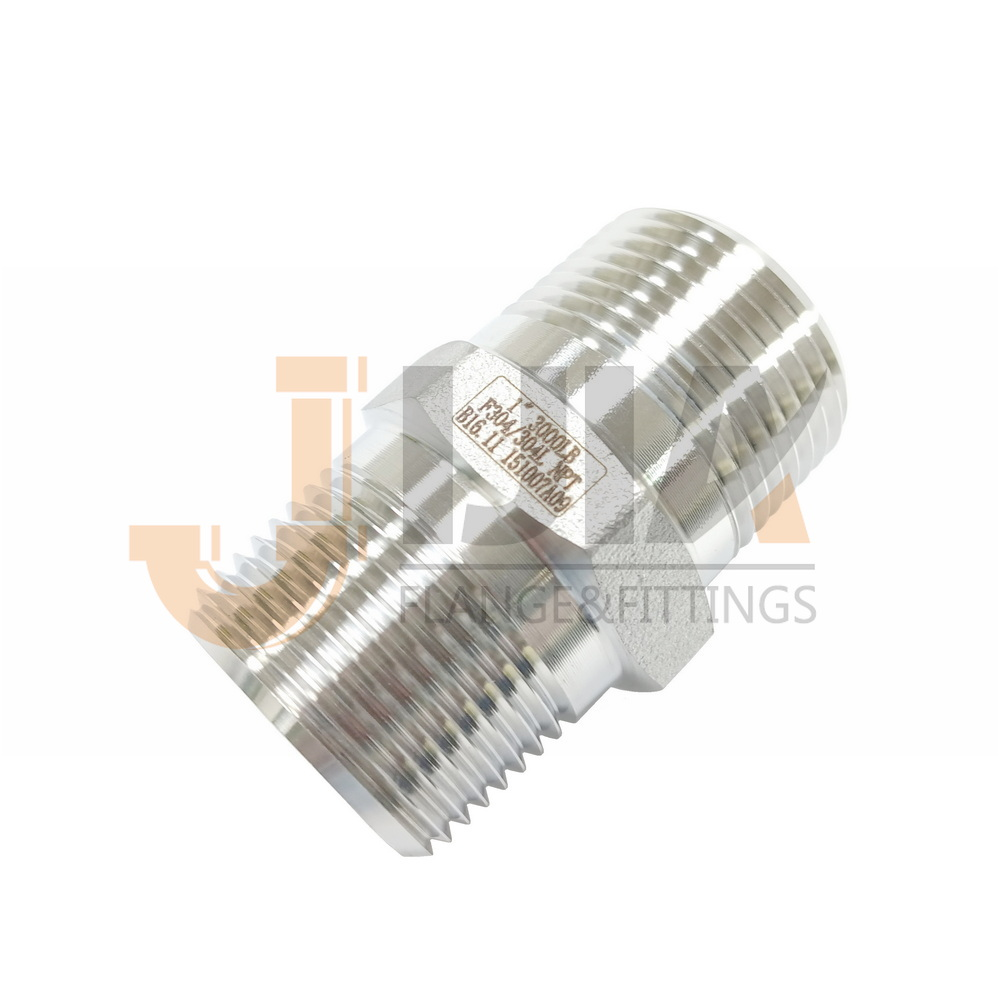

| Size | Type | Pressure | Material | Standard |

| DN6-DN100 | Hex Nipple | PN10-PN40 | Stainless Steel: 304, 316, 321, 317L,904L ; Duplex Steel: S31803, S32750,S32760 ; Nickel Alloy: Inconel 600, Inconel 625,Hasta C276, Alloy 825, alloy 800, monel400 | ASME B16.11, ASME B16.28 |

Product Description

Forged hex nipples are manufactured using forging processes, offering excellent mechanical and connection properties. Suitable for pipeline systems requiring hex wrench installation and removal, commonly used for equipment interfaces and pipe connections.

Core Advantages

✔ High Strength: Forging process ensures high tensile and compressive strength.

✔ Precision Machining: Hex dimensions are accurately machined to ensure perfect fit with standard wrenches.

✔ Strong Corrosion Resistance: Multiple stainless steel and nickel alloy materials available, adaptable to various corrosive environments.